Thermal silica film is very important in LED high-power chip heat dissipation: LED thermal silicon film can be divided into chips according to chip size, and can be divided into small, medium and high power chips according to power. According to customer's request, it can be divided into single tube level, digital level, dot matrix level and decorative lighting. As for the specific standard size of the chip is based on the actual production level of the chip manufacturer, there is no specific request. Only skill pass, the chip can advance unit output and reduce the cost, the photoelectric function will not change.

The operating current of the LED chip is actually related to the current density flowing through the chip. The chip uses a small current, and the chip uses a large current, and their unit current density is almost the same. Assuming that the current of the 10 mil chip is 20 mA, then the 40 mil chip can theoretically use a current of 16 times, or 320 mA. However, considering that heat dissipation of the thermal silica film is the primary problem under high current, its luminous power is lower than that of a small current.

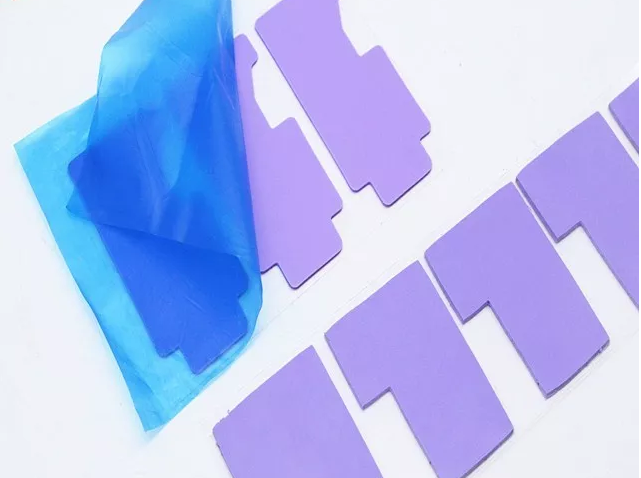

On the other hand, since the area is increased, the body resistance of the chip is lowered, so the forward conduction voltage is lowered. The LED high-power chips used for white light are generally visible at 40 mils in the market. The so-called power consumption of high-power chips generally means that the electric power is above 1 W. Since the quantum power is generally less than 20. Most of the electric energy will be converted into heat energy, so the high-power LED lamp chip uses the heat-conducting phase change paste or the heat-dissipating silica gel sheet to dissipate heat very first, so that the chip has a large area.

It is well known that in the future, LED light will decrease with the increase of the junction temperature of the chip, and the light efficiency will decrease. This is the inherent physical property of the semiconductor with temperature changes. The use of thermal silica gel sheet needs attention, only a certain part of the LED light source does not exceed the temperature limit and the LED is interrupted. After the temperature is restored, the light intensity will be restored as it is, that is, the LED does not matter how long it works, only the initial light intensity is not Change can not be considered as light decay. LED light decay refers to the failure scene of the LED light source that is no longer recovered due to some data hazard, that is, the ratio of the loss of luminous flux (initial light intensity) to the lossy luminous flux (attenuation failure light recovery) of the LED light source in a regular time.